Click HERE here

to join the Metfab e-mail list to receive the latest news

Click HERE here

to view pictures of some of our specialty work

December,

2009 Newsletter

Happy Holidays, Merry Christmas &

Happy New Year!!!!!

On the cusp of another new year, Metfab Metals has added in 2009 more successful jobs, experience, technology and a resources/outsources base to help you with all your projects---small or large, simple or sophisticated, computer-designed or ‘scratched on a napkin’---or whatever. We hope 2009 was good for your business (that you survived this recession economy is a testament to the hard decisions you must have made, as Metfab Metals has).

What we wrote in this space last year is worth repeating:

“…………… (W) e realize that our nation’s economy has been hurt in a number of sectors this (past) year that may take years to recover. If you have hit a rough patch, maybe we can work with you this year to again move forward. We are every day working on new concepts, GREEN technologies and the path to the coming “Green Economy” that many forecast. Our work on the LEED certs of 2008 are now morphing into the LEED-CS’s of 2009. We’ve fabricated and assembled for many sectors of the building construction industry, but now are reaching out to the wind-power and alternate energy fields to add our expertise to help with all their evolving needs. As we see it, if we can fabricate anchors, beams, embeds, AESS steel, curtainwall support steel, aluminum parts and all manner of miscellaneous metals, why can’t we make windmill parts and the constituent parts of their support structures or solar power structures?”

Last year we had just finished this architectural beauty and restoration rendered below at 51 Louisiana Avenue in Washington, DC! We are about to finish additional work at the American Jewish Heritage Museum in Philadelphia. We also erected (and now have dismantled) the model for the WTC4 façade for the Ground Zero rebirth. With its start, we look forward optimistically to 2010 for big new jobs----and lots of modest, even small, ones. Come work with us. You’ll find the type of quality, dependability and capacity to innovate that Larry Silverstein (legendary developer of the new World Trade Center) smiled agreeably about when we featured him in our August, 2009 Newsletter

************************************************************************************************************************

Happy Holidays! Merry Christmas! Happy New Year!

And have a great 2010, working alongside us, here at Metfab Metals!

October/November, 2009 Newsletter

PROJECT OF THE YEAR!

Metfab’s Work for the Future WTC Model Is Done

as the VMU is dismantled!

Our regular readers and customers know how proud we were to be involved in contributing to this unique VMU (“visual mock-up) for the rising WTC4. Look back at earlier newsletters on this site for even more info on this “once in a lifetime” job. Of course, we have built other mock-ups (and our existing “pad” is now available if you have a job that needs a real-life, real-time model for owners, architects, engineers & perhaps others to judge materials, break-through technologies and appearances), but this is now the model that will be used to assemble the facades of all the Ground Zero replacement buildings. This is work we hope to participate in also in 2010 and thereafter.

Our part here has been a challenging fabrication and job coordination for Metfab Metals from beginning to end. We are happy to report that it all was delivered, accepted and installed almost flawlessly, despite precisely designed and engineered plans to produce an exterior effect of utterly straight fifty-feet solid steel columns to produce the visual effect drawn by the architects. Take a long look at what was done here. Think how we can help you with your small----and large---projects. If we can innovate, coordinate and elevate our performance to get these multi-ton columns to tolerances demanded, can’t we help you on your job’s needs?

Call us; let us help you with all your fabrication needs!

Project

Updates:

United Nations Retro-fit, NYC, NY------We’ve been working on one aspect of this job or another for over a year now. More unique Metfab anchors are installed here almost daily. This job too started with a VMU!

National Museum of American Jewish Heritage, Philadelphia, PA-----Another “glass” job winding down to a successful conclusion. Our work for our glass customer, APG International of Glassboro, NJ, was recently completed. Metfab Metals anchors, curtainwall parts, 21st Century finishes, space-age paint and miscellaneous metals all went into this noteworthy building to a truly memorable effect.

Call me. Let me help with all your fabrication needs----and problems!

Jim

973-75-7676 or [email protected]

Take another look at our established products :

- Concrete Embeds (Halfen alternatives)

- AESS Steel

- Curtainwall Support Steel

- Stone Anchors

- Complex Metal Operations

- Steel Parts for Glazed Curtainwall

- ……and more

|

Also now:

• Sustainable (GREEN)

Building Materials

•

Low VOC Paints/Painting

•

LEED Certification Assistance

•

Aluminum Fabrication/Finishing/Painting

•

Environmentally Safe Plating/Finishing

•

Re-Usable Scrap Materials

•

Miscellaneous Building Envelope Parts

•

Miscellaneous Building Envelope Services

•

Energy Efficient Fabrication

•

Union Trucking Available---Up To 53’

•

Oversize Load Specialists

•

And Lots More---Call & Y ou Shall Find! |

September,

2009 Newsletter

“A glimpse of the new World Trade Center”

On Wednesday morning, August 19, 2009, New York City radio station WABC 880AM announced that “an Orange, New Jersey firm is giving us a glimpse of the new World Trade Center today!” That firm” is US----Metfab Metals, LLC!!--------Come take a look yourself at pictures throughout this site and our specific link.

Later, our yard & the surrounding area were swarmed with TV satellite trucks, reporters and camera equipment as our town recognized the contribution we are making to local employment and the national goal of rebuilding our WTC. Mayor Eldridge Hawkins of our town, as well as many officials and local citizens, came to our yard to view many months of hard work that went into our customer’s VMU or ‘visual mock-up’ of the façade of WTC4. (This was reported on the City’s official site at www.ci.orange.nj.us/news-081509-wtc-model.html)

Don Robinson and his wife Marcee’ said a few words about the effort that also recognizes the painful loss of their son Don, Jr. on 9/11. All of this can be seen on the above link too.

As our owner, Jim Murray said in one of many radio and TV interviews, the steel mullions are blast-resistant and the glass is reminiscent of what the iconic building looked like before the hateful attack of 9/11/01. This is another unique job Metfab Metals has completed for a customer like you. This VMU design will be replicated 27 times to complete the glass and steel enclosure of the lobby of this first WTC building.

Let us help with your fabrication “devils in the details”!!!

GREEN Update: On August 14, 2009 our staff completed a USGBC workshop reviewing all the basic concepts of GREEN building and current LEED requirements. Very ably and logically presented by Jason Kliwinski, AIA & LEED AP, this now gives us yet more familiarity with the needs of a contractor building a modern, efficient building envelope, as well as the point system compliance needed to qualify for Silver, Gold & Platinum LEED certification. Let us help you on the next project to finish a truly energy-efficient and LEED -compliant building.

Project

Updates:

United Nations Building, New York City, NY - Another job getting done in the Metfab Metals tradition----on-time, every time! We are making myriad miscellaneous metal parts for the retro-fit of this unique part of NYC architecture.

National Museum of American Jewish Heritage, Philadelphia, PA - Another unique job being done with our good customer, APG International of Glassboro, NJ and, in turn, for its customer, INTEC Construction, Inc. of Philadelphia! Here you’ll see Metfab Metals anchors, curtainwall parts and miscellaneous metals going into this worthy building with 21st Century finishes and space-age paint for all visitors to see for decades to come.

Call me. Let me help with all your fabrication needs----and problems!

Jim

973-75-7676 or [email protected]

Take a look at our established products :

- Concrete Embeds (Halfen alternatives)

- AESS Steel

- Curtainwall Support Steel

- Stone Anchors

- Complex Metal Operations

- Steel Parts for Glazed Curtainwall

- ……and more

|

• Sustainable (GREEN)

Building Materials

•

Low VOC Paints/Painting

•

LEED Certification Assistance

•

Aluminum Fabrication/Finishing/Painting

•

Environmentally Safe Plating/Finishing

•

Re-Usable Scrap Materials

•

Miscellaneous Building Envelope Parts

•

Miscellaneous Building Envelope Services

•

Energy Efficient Fabrication

•

Union Trucking Available---Up To 53’

•

Oversize Load Specialists

•

And Lots More---Call & Y ou Shall Find! |

July/August,

2009 Newsletter

World Trade Center Tower #4 Update:

The official viewing of our visual mock-up (“VMU”) of the exterior of the first six floors of this rising tower took place at our facility here in Orange, NJ in early July. In attendance were reps of Macki Architects, Silverstein Properties (the owner), Port Authority of NY/NJ, Tishman (the GC) and our curtainwall customer, Benson Global. The consensus was very favorable. Our plan now is to move forward with the process of materials procurement to scheduling production to all the work to get this big job done.

A few days after this formal viewing, we had the distinct honor of a personal visit by Larry Silverstein himself. He looked thoroughly at this huge chamber, asked us questions and agreed to a few photographs. His parting comment, “I love it.” We are extremely proud of our accomplishment on this monumental project. I guess you can see Mr. Silverstein’s approval in his picture below that day with our owner, Jim.

Jim Murray & Larry Silverstein

Silverstein Properties’ own public relations crew visited us also. They videotaped the VMU and our entire fabrication shop. They interviewed Jim who commented at length about our execution of the VMU process. You can see this interview live by visiting their project website set up exclusively to cover all the ongoing construction events at the WTC Tower #4 ( www.wtc.com).

But, of course, as the VMU is done, we are still doing other large (and small) jobs for our many old---and new---customers. As we move forward this summer, we are looking to starting our next “name” project-----The United Nations Building “renovation” in New York City also. Our job will be to provide structural reinforcement assemblies, as well as miscellaneous steel. We will be storing fabricated materials and delivering them on demand….another service we offer that makes Metfab Metals a valuable resource.

Project

Updates:

B.R.A.C. - This job was nothing short of a masterpiece of AESS and precise finishing. Look at this picture of the installed exposed ‘ladders’!

Finished B.R.A.C. Headquarters Job!

National Museum Of American Jewish History – We are into the CW5 area. Fabrication is going well. We are looking forward to getting into the more complex steel fabrications in the upcoming weeks.

UN Building “Mobile” VMU - We are here fabricating a movable or ‘mobile’ visual mock up (“MVMU”) for this NYC job. We built the structural steel frame, then the metal stud walls and then covered them with finished plywood panels. After assembly and approval, we disassembled all of this and delivered it to the UN site to be re-assembled and displayed at various locations onsite during the course of the project. This MVMU is 8’ X 17’ X 14’. Look at the picture below.

**********************************************************************************

Work with us throughout 2009

Metfab Metals!

***********************************************************

“We work on YOUR time.”

May/June,

2009 Newsletter

Metfab Metals Moves Forward With High Hopes & Determination For Spring/Summer ’09!

The winter season has finally passed, and with this comes an array of new energy and enthusiasm here at Metfab Metals. Our variety of plans for this summer consists of so many different challenges in which we are really looking forward to accomplishing. With the final completion of the Visual Mock-up for the World Trade Center - Tower #4, that we have been so proudly proclaiming for the last several months, gives us the initiative to now move forward and reminisce on the long months of hard work done by our customers, clients, and employees. The time has begun for us to move into the production phase of this valuable project.

We are already in the midst of production regarding the Embeds for Tower #4, and understand the strict guidelines that will govern our fabrication processes and inspections. Metfab Metals is more than ready for this challenge! The purposed “Bomb Blast Requirements” have substantially increased the member sizes and weld procedures for this project. Similar requirements will also be addressed for the One World Trade Center project, which we are working extremely hard at finalizing our proposals and applying our expertise to the fabrication process as well as Value Engineering. This is a great challenge that we as a team are more than willing to conquer. As once stated by Winston Churchill, “Difficulties mastered are opportunities won”, and this is our motto to live by this summer.

Opportunity is what comes out of a challenge, but only if the challenge is adhered to successfully. Our philosophy at Metfab Metals is to take a project that works, and then collaborate with our customer in every way possible so that the outcome is complete satisfaction. This is what Metfab is expected to do, and what we do so well.

In the coming weeks we will be giving you indebt reports on our progress, and later in the month, we will introduce our new “Job Cam”. This will enable you to log into our website, see our shop and the fabrications as they are actually happening, and even be able to actually interact and ask any questions that you may have about our processes and how we can help you master any of your current or future projects! Simply have your estimator or project manager contact us for further information at any time! Information is power, and our goal is to share it with you in a constant effort to win your business! We wish you all a great summer season here at Metfab Metals!

Project

Updates:

Jewish Heritage Museum – Philadelphia, PA -This new project consists of AESS quality steel at its best. Our customer chose the right company for this highly visible exposed curtain wall system. We have the plan, and are moving forward to making this yet another success for Metfab and most importantly, another satisfied customer!

One World Trade - “Bomb Blast Criteria Embeds”

Our first release of the embeds for the glass wall at One World Trade are well underway. These are serious embeds both in structural mass and fabrication. Metfab has the capability, and we look forward to meeting all of the structural and AWS requirements as well as completing the order on a time sensitive deadline.

April,

2009 Newsletter

Metfab Metals Offers Another New & Valuable Service To

Our Customers…Stainless Steel Polishing!

Metfab Metals is proud to announce our new stainless steel polishing services located at our Orange, New Jersey facility. Normally, our stainless steel orders must be outsourced after its fabrication in order to be polished, but now our company provides the option for our clients to have everything done in house! Our full service stainless steel polishing line will enable us to polish most Stainless finishes. Having this ability to polish our own fabrications gives us the opportunity to not only control quality, but also ensure timely deliveries.

Our company is capable of polishing any alloy in whatever finishes

our customers desire. For stainless steel, we have a pipe capacity of up to 8” diameter, sheets of any size, and every possible available bar stock. Of course, we would also be more than happy to fabricate or weld as well, if applicable. With the completion of the custom stainless steel curtain wall towers for the B.R.A.C. project, which was previously featured in several of our past newsletters, we are extremely confident in our abilities in this endeavor, and we look forward to continuously providing more services in the future.

In addition to our polishing capabilities, we are also currently planning on adding advanced robotic welding into our weld shop. A number of our upcoming projects require us to be innovative in our equipment, and as always Metfab is constantly updated on the latest and greatest technological advances in order to advance production time, meet strict deadlines, and streamline pricing to stay competitive in today’s difficult economic environment.

We ask that all of our customers take these factors into consideration,

and let us provide your projects with the best all-in-one services out there!

With these great new prospects, we hope to better manage the timing and overall production of all of our jobs to a grade A level of high quality and performance. Please take advantage of these services that will not only help you streamline your project material processes, but most importantly, insure that your

job comes out ‘top notch’!

Project

Updates:

World Trade Center – Tower #4 -

The VMU steel has officially been completed, and the glass wall erection begins next week, which we have been anticipating for quite some time! We have tested our dry fit to ensure that all of the major components would fit prior to the erection, and we are very pleased to report that all went according to plan successfully.

New Campus East -

We are currently in the early stages of another Washington DC project. Miscellaneous fabricated steel and embeds, along with Monorail systems are now in effect.

Call me. Let me help with ALL your fabrication needs--and problems!

Jim Murray

Owner

Met-Fab Metals, LLC.

560 Freeman Street

Orange, NJ, 07050

Ph: 973-675-7676

Fax: 973-675-7446

E-mail: [email protected]

PS: Please feel free to share all of the new information you now have about Metfab Metals with your fellow colleagues! Our company is always looking for new clients and opportunities for great projects. Remember we are here to help with ALL of your fabrication needs. Metfab Metals has the capabilities of a large factory, but can still focus on the smallest tasks and inquiries. Our goals are limitless, and we strongly believe in business-to-business practices. We can help you with anything. We’re just a phone call away!

All bids can be placed with Christopher Desimone, Metfab’s Project Coordinator and Estimator.

E-mail Chris at: [email protected]

Or call: 973-675-7676

Also now:

*******************************************************************************************************************************************

• Sustainable (GREEN)

Building Materials

•

Low VOC Paints/Painting

•

LEED Certification Assistance

•

Aluminum Fabrication/Finishing/Painting

•

Environmentally Safe Plating/Finishing

•

Re-Usable Scrap Materials

•

Miscellaneous Building Envelope Parts

•

Miscellaneous Building Envelope Services

•

Energy Efficient Fabrication

•

Union Trucking Available---Up To 53’

•

Oversize Load Specialists

•

And Lots More-----Call us and let us serve your business |

March,

2009 Newsletter

Re-constructing The World Trade Center, Tower #4 – The Project of a Lifetime…

The moment has finally arrived! One that many American’s have been waiting for since the tragic events of September 11, 2001 occurred in New York City. Families of victims, loved ones, relatives, and friends who have remained patient and hopeful for the past seven years, will finally have the ability to obtain closure with the re-building of ground zero. This topic has been talked about since the year 9/11 took place, and we have all heard many different stories, ideas, and plans for what would come of the new World Trade Center. We now have some of the answers that you have all been waiting for, that will hopefully put an end to the confusion many of us have experienced.

Our company is extremely proud and honored to have been selected to be a part of the new re-building of ground zero. This project is extremely important to us, mainly because of the symbolism behind the word “re-building”. The overall meaning of when we get knocked down, we get right back up again! Metfab looks at this project as a major symbol for our country, the people, and the world. In being a part of this new re-building and total re-construction of the new World Trade Center, we hope to lift the spirits of our country, honor and pay tribute to those whom we had lost, and celebrate life and the spirit of what America stands for, to the fullest!

“You can be sure that American spirit will prevail over this tragedy”, stated former Secretary of State, Colin Powell, shortly after the events of 9/11 took place. The new World Trade Center/Freedom Tower will be a standing, solid, and symbolic representation of what American spirit stands for. The fact that our country will rise and stand together, high and tall, and most of all proud, which is exactly what Freedom Tower represents. This project will be one of our company’s most precious and monumental accomplishments ever. We are so proud to be a part of not just a major project in our country’s history, but more so--the beginning of a new level of American spirit.

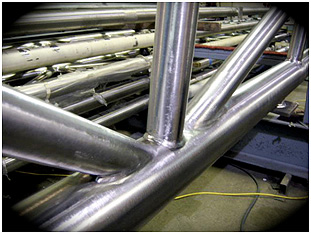

“For our company, this truly is the project of a lifetime. It is an extremely personal involvement for us, and we will devote our complete maximum dedication and talents each step of the way”, states Jim Murray, Owner. Presently, Metfab is in the beginning stages of the process, where we are currently building the visual mock-up for Tower #4 right in our shop’s front yard! Metfab has also already provided the embeds for the foundation of the Freedom Tower. In the near future, Metfab Metals will also be providing all of the steel for the glass walls as well. Metfab is waiting on further releases regarding this project, and will continue to keep you updated!

WTC VMU Camber Steel

Courtesy of Metfab Metals (3.17.09)

Project

Updates:

Crosby Street Hotel – Manhattan, NYC -----

We have completed our work on the Crosby Hotel in lower Manhattan. It has been quite a challenge to make new steel look old. Metfab successfully created the look the architect wanted and delivered the project on time as always!

B.R.A.C. Headquarters ----- Metfab received the contract to fabricate the upper and lower connections for the Stainless Steel trusses. Currently, we are water-jet cutting and making final touches on assembly.

Call me. Let me help with ALL your fabrication needs--and problems!

Jim Murray

Owner

Met-Fab Metals, LLC.

560 Freeman Street

Orange, NJ, 07050

Ph: 973-675-7676

Fax: 973-675-7446

E-mail: [email protected]

PS: Please feel free to share all of the new information you now have about Metfab Metals with your fellow colleagues! Our company is always looking for new clients and opportunities for great projects. Remember we are here to help with ALL of your fabrication needs. Metfab Metals has the capabilities of a large factory, but can still focus on the smallest tasks and inquiries. Our goals are limitless, and we strongly believe in business-to-business practices. We can help you with anything. We’re just a phone call away!

All bids can be placed with Christopher Desimone, Metfab’s Project Coordinator and Estimator.

E-mail Chris at: [email protected]

Or call: 973-675-7676

Also now:

******************************************************************************************************************************************

• Sustainable (GREEN)

Building Materials

•

Low VOC Paints/Painting

•

LEED Certification Assistance

•

Aluminum Fabrication/Finishing/Painting

•

Environmentally Safe Plating/Finishing

•

Re-Usable Scrap Materials

•

Miscellaneous Building Envelope Parts

•

Miscellaneous Building Envelope Services

•

Energy Efficient Fabrication

•

Union Trucking Available---Up To 53’

•

Oversize Load Specialists

•

And Lots More-----Call us and let us serve your business |

February,

2009 Newsletter

A Dedication to Metfab’s Greatest Assets: Teamwork and Real Estate!

There comes a point in every business, which many of you know, when we must take a step back and pay tribute to what really keeps our business at the top level of outstanding service and growth. Fortunately, Metfab Metals continues to experience this on a daily basis. We attribute most of Metfab’s success to our dedicated team of employees along with the space in which each day they put their blood, sweat, and tears into every project that enters any one of our five locations. This has been the key to our success. This month, our goal is to reflect on our employees and on our shops, and really take a look at the big picture on how our company is able to continue providing you with the best level of service in the business. While doing so, we hope to educate you on some of the history of our business, how we operate on a daily basis, and the people who are responsible for bringing our best projects to life.

Metfab Metals has continued to grow throughout the past decade in many different ways. Of course, a main reason being the impeccable talents of Jim Murray (Owner/CEO), who can be mainly held responsible for the image and success of Metfab Metals today. On the other hand, our company has also been very fortunate to bring forth some of the best minds in the business, and put their hands to work! Metfab Metals separates our services into five main locations, all of which contain their own unique capabilities and specialties, along with the outstanding individuals who keep it going. These include:

Metfab Metals Primary Fabrication Building/Administration – 560 Freeman St., Orange, NJ

This location is the core of our business. In this shop, various grades and types of material are cut, punched, or machined into all types of building components. This location is also the home to our Stone Anchor processing line. This consists of several progress dies and some compound dies as well, all of which are built in house; in order to perform specific tasks needed to produce the required stainless steel anchoring necessary for the installation of natural stone or glass, for both commercial and residential use. Every single part for every project is closely monitored for strict quality control guidelines before reaching their destination for further processing. Ed Huneke, whom serves as our leading man in this department, with his direct production supervision, coordinates the daily influx of orders, streamlines them through the various fabrication channels, and finally ensures that they arrive at the appropriate phase of further fabrication, with his key objectives in mind: quality and on time delivery! This enables our welding team the ability and confidence that each project is precisely done to its ultimate potential. Ed also plays a major role in our production planning and his experience in the overall fabrication end of the business and team player attitude is a valuable asset to the success of this Metfab location.

We strongly believe that 80% of a projects success is involved in the early stages of the planning process. Every project Metfab does first goes through the estimating stage, Chris Desimone, our chief estimator moves forward by handling each step of this process, in which he has continued to succeed since our company's inception. Chris is known to dissect a project to its bare essentials, plot the materials, supplies, and labor, while supporting the continuous flow of questions and problem solving to our customers. Our customers know they can rely on Chris for his expertise in providing the best possible way to supply the steel requirements for their projects in the most economical way without diminishing quality or schedule. Chris is on most of our customers' speed dials for answers to their questions when it comes to all related inquiries regarding their projects. Computerization, CAD, and using multiple programs concurrently to perform the tasks necessary to hand our fabrication teams precise documents that they can rely on is another one of his skills. Chris also continues to search for the latest advances in technology in order to help make us a great source for solutions to our customers.

Chris Desimone Ed Huneke

Metfab’s Welding and Assembly Plant – 44 Stockman St., Orange, NJ

The entire focus of this location is directed towards the materials that require assembly and welding. This is the shop where we begin to see our projects come to life. A majority of the parts, which coordinate with our primary location based upon the production schedule at that time, are then placed into the welding and assembly process here. This location is highly equipped with the latest welding technology along with all jigs and fixtures needed to fabricate. It is a mandatory requirement that each our welding employees be AWS certified in four different classes. Just another quality that makes our welding team at Metfab Metals highly qualified for ANY type of welding projects and situations.

This shop is overseen by one of our leading foreman's, Pablo Chang, who serves as our production supervisor. As an industry leader in AESS (Architecturally Exposed Structural Steel), Pablo's last three projects relied mainly on high quality AESS standards, all of which can be demonstrated in his work - and speak for themselves. Our website, (www.metfabmetals.com) depicts a wide range of completed projects that directly show the outstanding work in which Pablo and his team delivers on a regular basis. Our project of the year, 51 Louisiana, as highlighted in our December 2008 newsletter, clearly demonstrates Pablo's skills as a team leader, and master fabricator.

Pablo Chang

Metfab Metals Stainless Steel Fabrication & Welding Shop – 44 Tomkins Street, Orange, NJ

Metfab takes great pride in our Tomkins Street shop because of the fact that it is totally devoted to our true love, stainless steel. This factory has been decontaminated from all other metals to ensure that our fabricated stainless steel projects are free from all other contaminates (such as carbon steel, tool steels, and even certain aluminum). All tools and equipment within this facility are kept separate in order to completely prevent contact with dissimilar metals.

Pablo Change and Ed Huneke team together and manage the operations within this location in addition to their regular duties. This can be considered as a prime example of two people who collaborate both of their experience in other areas, and continue those skills while multi-tasking.

This Metfab location is also home to our shipping and receiving warehouse. At Metfab, we believe strongly that our fabrication procedures would mean nothing unless they ensure on-time delivery and secure packaging. Ralph Murray excels in this department as our main supervisor responsible for ensuring our customers that their product will arrive on-time and in top condition. Specific customer packing instructions are taken very seriously, and we understand the importance of labeling, crating by area, floor, or other requests. Communication is vital, which is why we notify our customers in advance of delivery, as well as provide solutions to unloading and logistics when warranted.

Accounting & Sales – 340 West Passaic St., Rochelle Park, NJ

Our appreciation to the accounting and sales team at Metfab is enormous. Lauri Murray, head of all financial facets of our company, along with her assistant Kenya Roberson, keep our financial operations flowing in the right direction. They understand that we are only as good as our vendor and value their service and see to it that they are paid promptly. Our constant monitoring of our purchases and confirmation of their deliveries are paramount to our production teams and Kenya is relentless in her efforts to ensure our clients get what they need on time.

Kenya Roberson

Marketing & Public Relations – 180 Riverside Blvd., NY, NY

Our image as a company, and our reputation in the construction industry are Metfab Metals greatest pride and joy. Our company has always put our best foot forward when it comes to completing our projects on time and making sure they reach their greatest potential. Metfab Metals has complete confidence in our new PR and Marketing Director James Murray Jr., and that he will excel in his efforts to communicate with our existing customers as well as new ones.

Delivery – All Locations

All of our companies efforts, fabrication, administration, and sales wouldn’t mean much if we couldn’t deliver. We have the fleet, and the experienced drivers to do what it takes to deliver on time!

Steve Bader, Metfab’s driver with over 25 years of experience, works directly with our customers to ensure that deliveries are made on time and to our clients’ ultimate expectations. Service is what we are all about; therefore, working hard to make our customers happy is what we do best. For our local and long distance rush deliveries, Willie Stackhouse is our go-to-guy. Willie has been with Metfab Metals for years, and has continued to prove his image of reliability.

Metfab’s new top-of-the-line commercial delivery truck

As you now know, Metfab Metals takes great pride in our employees and all of the wonderful skills each one of them brings to our organization as a whole. Thus being the main reason we chose this month as a pure dedication to the people who have built the reputation of Metfab Metals profoundly based on their talents, word, and individual mastery of their own unique tricks of the trade. Our company is extremely fortunate to have this team with us, while we continue to deliver our promise and commitment to excellence.

Project

Updates:

BRAC Headquarters - Andrews Air force base:

The final assembly has been completed and we are now in the polishing phase. Each ladder has been rigorously inspected and re-worked to provide a nice uniform finish that meets or exceeds the projects specification.

World trade Tower #4:

Old Mock-Up is down. Ground breaking for our next visual mockup “ Tower #4” is beginning.

Call me. Let me help with ALL your fabrication needs--and problems!

Jim Murray

Owner

Met-Fab Metals, LLC.

560 Freeman Street

Orange, NJ, 07050

Ph: 973-675-7676

Fax: 973-675-7446

E-mail: [email protected]

PS: Please feel free to share all of the new information you now have about Metfab Metals with your fellow colleagues! Our company is always looking for new clients and opportunities for great projects. Remember we are here to help with ALL of your fabrication needs. Metfab Metals has the capabilities of a large factory, but can still focus on the smallest tasks and inquiries. Our goals are limitless, and we strongly believe in business-to-business practices. We can help you with anything. We’re just a phone call away!

All bids can be placed with Christopher Desimone, Metfab’s Project Coordinator and Estimator.

E-mail Chris at: [email protected]

Or call: 973-675-7676

Also now:

*******************************************************************************************************************************************

• Sustainable (GREEN)

Building Materials

•

Low VOC Paints/Painting

•

LEED Certification Assistance

•

Aluminum Fabrication/Finishing/Painting

•

Environmentally Safe Plating/Finishing

•

Re-Usable Scrap Materials

•

Miscellaneous Building Envelope Parts

•

Miscellaneous Building Envelope Services

•

Energy Efficient Fabrication

•

Union Trucking Available---Up To 53’

•

Oversize Load Specialists

•

And Lots More-----Call us and let us serve your business!

January ,

2009 Newsletter

New Year, New Plans, NEW YORK for Metfab Metals!

January 7, 2009

New York City has forever been known as an ever-growing market within the construction industry. In recent years, this concept has dramatically flourished. Whether you take a drive on the Westside Highway, or stroll along the outskirts of Central Park, guaranteed on almost every corner you will come across those big blue “post no bills” wall coverings or scaffolding alongside pretty much every other building. What does this mean to us? Work!

In New York City alone last year, construction generated more than $30 billion in economic activity. New York is currently in a time of great potential as more projects are on the rise, or as the industry refers to it as “The Golden Age”.

Fortunately, Metfab Metals has been a proud participator in this era of business.

With that being said…Metfab Metals is proud to announce the launch of our new office located on Manhattan’s Upper West Side! The New York City office will focus directly on Metfab’s marketing, advertising, and public relations sectors of the company. Considering Metfab Metals has recently developed numerous projects within New York (including the new re-building of the World Trade Center, Tower #4), we now have a new space and presence directly in the heart of the city in order to devote our time into and better manage all of our New York projects.

Metfab Metals would also like to announce a new member on board! James A. Murray Jr., whom was recently appointed as Metfab’s new Marketing/PR and Sales Director. “It’s a new year, and we have so many new concepts that we are working on incorporating into Metfab’s new marketing plan. I am very excited to continue doing what I love to do, while learning and helping my father’s business grow”, says James Jr. of his new position at Metfab. James Murray Jr. has recently earned a BBA degree in marketing from the Laboratory Institute of Merchandising, located in New York City. James Jr. has also accomplished a wide range of experience under the business umbrella of marketing and public relations through apprenticeships at firms such as the Versace Press Office and LaForce + Stevens Agency.

With the New Year upon us, along with fresh new ideas on the rise, Metfab Metals has many goals and aspirations for our business in which we plan to accomplish mainly within our marketing department. As we continue to grow, so do our customers and colleagues from all walks of life. All of our new plans for 2009 rely mainly on our hallmark commitment to reliability in order to better serve our new, existing, and potential customers. We wish you and your business all the best for 2009!

Best Regards,

Jim Murray, Owner

We are moving ahead with our plans to get involved in not only aluminum fabrication, but aluminum assembly as well. The rendition above of our next project 250 west 55th street will be our first involvement in the actual assembly of curtain wall components. Our scope of work includes most of the standard processes such as milling, drilling, adhesive application, and final packaging. We are proud to have reached this stage of production as a company, and are set on using this experience as a platform for our involvement in aluminum fabrication and assembly in the future.

Our goals for the New Year are to forge ahead with our plans to stay in the forefront of our industry when it comes to fabrication and innovation, while paving the way towards the first Green fabricator.

Give us a call! Let us help you with ALL your fabrication needs-and problems

Project

Updates:

United Nations Retro-fit , NYC, NY ----- Another job complete to its finest! Metfab’s unique anchors that include customized covers are being made and installed as we post this. More news on this job in coming months!

BRAC ANG Headquarters ----- is progressing along. These solid stainless steel welded and polished assemblies are dazzling!!!!

With an overall length of near 40’0, they will definitely be the showcase of this project.

Call me. Let me help with ALL your fabrication needs--and problems!

Jim Murray

Owner

Met-Fab Metals, LLC.

560 Freeman Street

Orange, NJ, 07050

Ph: 973-675-7676

Fax: 973-675-7446

PS: Please remember to also take advantage of our established products and skills with the production of our custom Concrete Embeds (Halfen alternatives), AESS Steel, and Curtainwall Support Steel! We also specialize in Stone Anchors, Steel Parts for Glazed Curtainwall, and much more. Let Metfab Metals help with your complex metal operations. We provide solutions to help your project(s) reach its ultimate potential!

Also now:

*******************************************************************************************************************************************

• Sustainable (GREEN)

Building Materials

•

Low VOC Paints/Painting

•

LEED Certification Assistance

•

Aluminum Fabrication/Finishing/Painting

•

Environmentally Safe Plating/Finishing

•

Re-Usable Scrap Materials

•

Miscellaneous Building Envelope Parts

•

Miscellaneous Building Envelope Services

•

Energy Efficient Fabrication

•

Union Trucking Available---Up To 53’

•

Oversize Load Specialists

•

And Lots More-----Call us and let us serve your business |